Planning & Preparations

AME MAINTENANCE COMPANY : ADVANCED MECHANICAL ENGINEERING

Maintenance

Planning AND PREPARATIONS

Preparation of Maintenance Activities

AME elements of the preparation work include

- Entering machines and updating the machine directory including picture navigation in the maintenance system.

- Decisions and registration of spare parts to be held in stock and linking them to objects in the maintenance system.

- Entering spare parts requirements and time expenditure for recurring maintenance activities, including autonomous maintenance into the maintenance system.

- Developing preventive maintenance instructions.

- The labeling of equipment in the form of inventory numbers and lubrication points, etc.

- Registration of changes to machinery and equipment and updating the related maintenance documentation.

Maintenance

Preventive and Corrective

Preventive Maintenance According To Standards

Measures carried out intended to assess and/or to mitigate degradation and reduce the probability of failure of an object.

#1 : Condition-Based Maintenance

Preventive maintenance which includes assessment of physical conditions, analysis, and possible measures. Control and monitoring of performance and characteristics can be scheduled, on request, or continuously Subjective or objective assessment.

#2 : Planning and consultation

Preventive measures carried out by established intervals of time or number of units of use, but without previous condition investigation

This could be, cleaning, lubrication, and replacement of components or spare parts.

#3 : Predictive Maintenance

Condition-based measures are carried out following a forecast derived

from repeated analysis or known characteristics and evaluation of the

significant parameters of the degradation of the item

Corrective Maintenance According To Standards

Maintenance is carried out after a fault recognition and intended to restore an object to a state in which it can perform a required

#1 : Deferred Corrective Maintenance

Corrective maintenance is not carried out immediately

after detection of a malfunction but is delayed by given maintenance directives. The work can be planned.

#2 : Immediate Corrective Maintenance.

Maintenance is performed immediately after the detection of a malfunction to avoid unacceptable consequences

Featured Resources

MODIFICATION & IMPROVEMENT MAINTENANCE

- Improvement Maintenance

- Modification Maintenance

- Spare part Management

- Spare part Management

Improvement Maintenance According to Standard

Combination of all technical, administrative,and managerial actions, intended to ameliorate the intrinsic reliability and/or maintainability and/or safety of an object, without changing the original function

The purpose of an improvement could be to:

- Eliminate defects

- Improve safety

- Improve maintainability

Improvement maintenance excludes measures aimed at improving the machinery in terms of speed and quality. The same applies to the adaption of equipment for a new product or new packaging. These measures are called Modifications.

Modification According to Standard

“ The combination of all technical, administrative actions, intended to change one or more functions of an object.”

The FEST Maintenance standards are:

- Modification is not a maintenance measure but refers to the modification of a unit’s required function into a new one.

- Modification does not mean replacement with an equivalent unit.

- Modifying a unit can be a task for the maintenance organization.

Assessing the need for spare parts :

- Should you choose to harbor reserves or summon them as needed, a system of enchantment for spares control and safekeeping shall be essential. Contemplate the following enchantments:

- Welcoming components into the realm

- Enchanting the division between mended and untamed parts

Data Assessments :

- Safeguarding works in progress

- Cataloging and valuing requested spare parts for assignments

- Sending out functional items

- These endeavors demand chambers, storage units, specialized software for part management, and skilled attendants to maintain vigilant oversight.

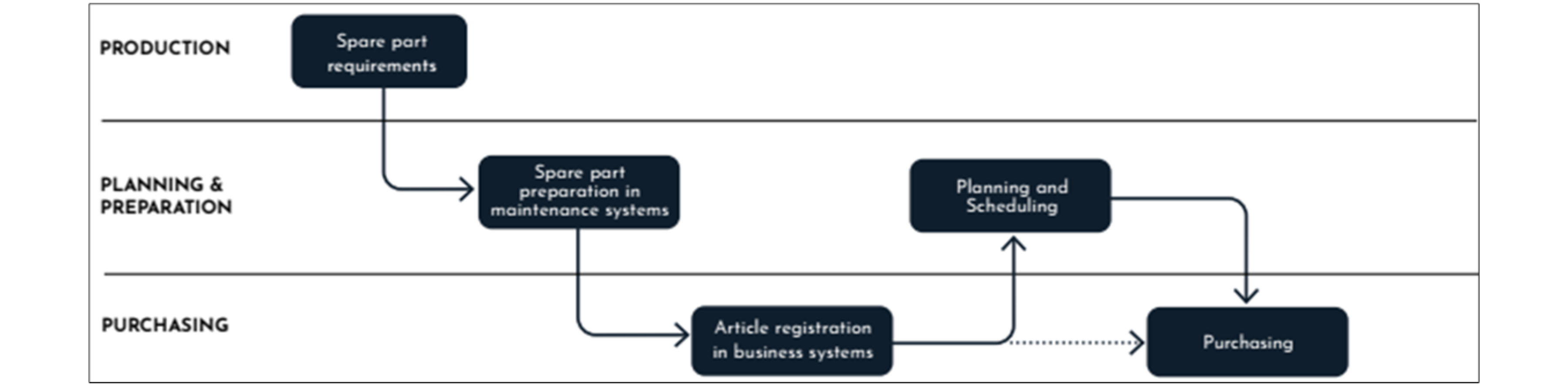

Spare part preparation and registration

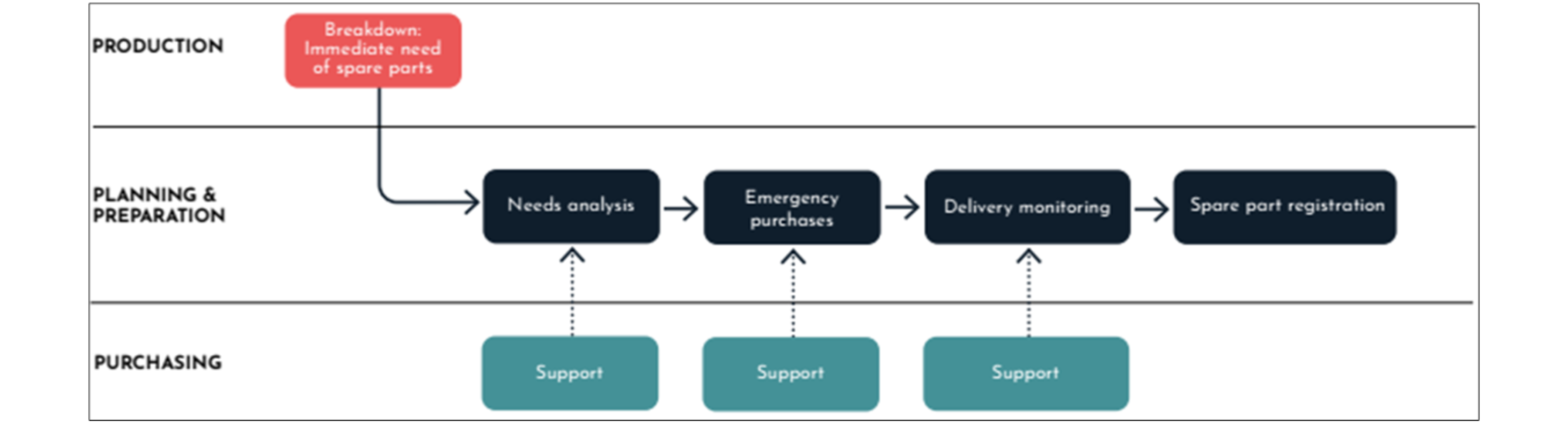

Immediate spare part need (non-stock item)

AME Maintenance Co.,Ltd

238/117 Moo 1 Karnchanavanish 63 Road Khaolupchang Muang Songkhla 90000

Tex ID : 0905566001906

Tel : 074-800362 Fax 074-436148